|

Home About us History of the First 1965 GT350; 5S003 1965 GT350 unique parts 1965 GT350 Mustang "By the Numbers" Literature and Memorabilia Shelby American employee stories Original owners stories Other 1965 GT350 stories Forums Links |

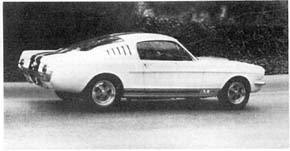

History of the 1965 GT350 and 5S003 (Updated: 7/13/21)(Click on any picture to link to a larger image)The first Ford Mustangs were introduced at the New York World's Fair on April 17, 1964 to rave reviews. A blitz of television commercials on ABC, CBS and NBC the day prior to its introduction, as well as having 11,000 Mustang press packets sent to newspapers and magazines throughout the United States fanned the fire. This resulted in large numbers of people gathering at Ford dealerships just trying to get a glimpse of this new car. By the end of the first opening day, 22,000 orders had been placed for the newly styled automobile. By the end of 1964, over 263,000 Mustangs had been sold. The original sales estimates by Ford for the first year of production were off by over four times! Almost 419,000 Mustangs were sold by April 1965. This set a new record for the largest number of cars sold for an introduction of a new model. A sporty high performance (K-code) Mustang version was introduced in late June 1964. Three body styles were available for the 1965 model year: the notchback coupe, the convertible and the slippery new fastback. By this time, a craze was taking hold of a rather large group of generally younger automobile drivers, which we have now termed the muscle car era. Chevrolet had been building the Corvette for the past ten years and their top-of-the-line model for 1964 was the fuel injected 327 coupe (3,180lbs., 375 h.p.). The 1965 Chevelle 327 L79 was priced $900 below the Corvette for the financially challenged hot-rodder (3,140lbs., 350 h.p.) Pontiac had introduced its mid-sized (read large) Tempest-styled body with a huge tri-powered 389 motor and named it the GTO, (3,178 lbs., 360 h.p.) The 260/289 Cobras (2,030lbs., 271 h.p.) had been out in the market for two years and in the proper hands, the nimble, lightweight, two seater probably ruled the street racing scene. At a base price of $5,995.00, the Cobras were $1,000.00 more than the Corvette. Needless to say, the new 1964 1/2 Mustang did not fit into this crowd very well. About this time Ford declared a "Total Performance" public relations campaign. The automotive giant began pumping a lot of money into just about every aspect of motorsports: Nascar, Indy racing, drag racing and sports car endurance racing. Ford's link to sports car racing was with a small company in Venice, California, Shelby American. By 1964, the Shelby Cobras had just two years of racing under their belt, but were racking up victories across the United States and were expanding to European racetracks in order to conquer Ferrari. The new Ford Mustang had been selling extremely well off the showroom floor, but it was far from a sports car and was not going to be considered as an addition to Ford's "Total Performance" program. It was no surprise when Ford approached the SCCA and told them they intended to enter the Mustang in the sports car class, their demand was quickly dismissed. What Ford failed to realize was that the SCCA was extremely independent and they did not like the idea of a large company dictating to them what they should accept. Ray Geddes, the head of Ford's Special Vehicle Department (Racing) suggested the logical choice was to have Carroll Shelby diplomatically work with the SCCA to determine what steps were needed to get the new Mustang active in racing. Geddes was able to convince an initially less than enthusiastic Shelby about taking on another full scale racing development program and production street car project. The two previous years of Ford's financial commitment with the 260/289 Cobras likely helped sway Shelby on the idea of agreeing to the Mustang program. The 289 Cobras were dominating their class in the national SCCA races and were in the midst of giving Ferrari a run for the World Championship title with their new Peter Brock designed Daytona Coupe. With Shelby's previous racing career, his vast contacts within the racing and automotive community, as well as his experience on how to promote a new car, it would have been difficult to have found a better person for the job. Shelby contacted John Bishop, the executive director of the SCCA, in the summer of 1964 and brought up the subject of what was needed to make the Mustang race worthy. A few days later, Bishop called Shelby back with a few areas to consider in modifying the Mustang. The points Bishop came up with included removing the rear seats (there were no provisions in the SCCA for a four-passenger race car), installing larger brakes, increasing the horsepower to around 300 and improving the suspension. Furthermore, SCCA's regulations allowed Shelby to modify the engine OR the suspension/brakes and the car would still be considered as a production car - but both areas could NOT be modified. Shelby determined he would have less trouble with warranty issues if the engine was kept stock. The idea of having the suspension and brakes upgraded for the race cars would not cause as much of a problem on the street cars warranty-wise. It is for this reason that both the race and street versions of the GT350 shared the same brakes and suspension. This way, Shelby's racing version could have a higher horsepower motor and still be considered "legal". Either way you look at it, this meant having to modify several major components of the basic Mustang! If that was not enough, they had to have 100 of them "ready" for the new homologation certification rules into B production racing by January 1,1965. That gave Shelby, with Ford's backing, just five months (August 1964- January 1, 1965) to get the job done. Not much time. Shelby relayed his findings to Lee Iacocca at Ford, who gave Shelby the go ahead on the project. Iacocca placed Geddes in charge of being the liaison between Ford and Shelby American on what was initially termed to be the 'Cobra Mustang' project. Sam Smith who was working under Geddes at the time suggested to a former General Motors co worker and friend, Chuck Cantwell, that he should contact Geddes about heading up the new project at Shelby American.

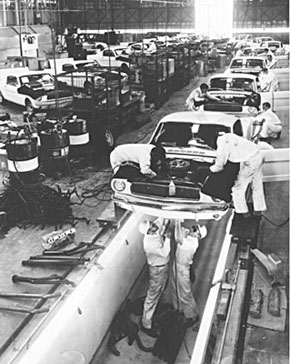

At this point, Shelby had less direct participation in this project because his plate was already full with both national as well as international racing. The last seventy five or so 289 Cobra street cars were being finished and the GT40 program was about to be inherited by Shelby American since Ford had not won a single race with the car prior to that point. The 427 Cobra project was also just about to begin, and oh, the Sunbeam Tigers were already being produced and raced. As you can tell, Shelby American was very busy, and for those who have visited the original factory buildings, things were quite cramped in late 1964. The engineering responsibility and coordination of the final parts design for putting together the GT350 Mustang, as we know it today, was mainly placed on the shoulders of Cantwell. A GT350 Production Team was formed which consisted of Cantwell, Bruce Junor and Jack Khoury; their first task was to form a sequence in which the new, unique parts could be placed on the Mustang at Shelby's plant. In a recent interview, Cantwell related that the Mustang project was already in full swing by the time he arrived in Venice. Ken Miles, Shelby American's Team Cobra driver and Competition Director, had built and tested two white 1965 Mustang HiPo 289 notchbacks with another Cobra Team driver, Bob Bondurant, as well as input from Klaus Arning, Ford's Chief Suspension Engineer. From what we can determine these two initial Mustangs were delivered to Shelby American in July of 1964. Cantwell added further information about how these two cars were used, "The two HiPo 289 Mustangs had been tested at Willows Springs with race engines, new suspension settings, traction bars and some other pieces to be used in the GT350 design. These cars had served their purpose and were hulks sitting in a back corner of the warehouse when I arrived on the West Coast. Ray Wolfe resurrected one of the cars and built it into a Trans-Am car which both Wolfe and I raced. We raced the car at the 1966 Riverside race, but did not finish due to engine problems. The race was won by Jerry Titus in a Shelby built customer car. The other stripped car at Shelby American was sold but apparently was never raced." The current whereabouts of these two cars is not known, but their VIN numbers are, according to factory records in SAAC's possession. A short time after Miles was finishing up with the pair of notchback Mustangs for their suspension development; another pair of white fastbacks was delivered to Shelby American in early fall 1964. These were placed in Brock's hands to develop their new outer appearance. One car was set up as a street version, with the initial hood scoop being placed further by the front of the hood than where it ended up on the production cars. This car also had a rectangular adhesive-backed foil emblem placed on the upper rear side of the front fender that said "Mustang G.T.", which was one the initial names given to the car. The second car was a racing/styling prototype which had a side scoop whose function would have been to aid in cooling the rear brakes. There was also a Monza-type fuel cap which was just simply placed on the passenger's quarter panel for display purposes, there was not even a special fuel tank designed yet. Another feature was the now recognizable R model rear window, which was designed by Brock to reduce the car's interior pressure hence lift and help maintain airflow over the rear of the car. Both cars were outfitted with American torque thrust mags and Brock's blue Le Mans stripes. Most likely these prototypes went back to Ford when they were no longer of use to Shelby. Very little else is known about these two cars. It is safe to say that hot rodding was born in Southern California during the late 1940's and early 1950's. By the early 1960's, Shelby American had gathered some extremely talented and well respected fabricators; Phil Remington, Bill Eaton, John Ohlson and John Collins, mechanics; Jack Hoare, Charlie Agapiou, and Ron Butler just to name a few. Shelby also put together a great infrastructure within Shelby American by adding Al Dowd, who initially started as a mechanic but quickly assumed a role in providing team management as well as organizational responsibilities, and Ken Miles, who was a seat-of-the-pants engineer and development driver. Hot rodding companies and speed shops were seemingly all over California; Hilborn, Edelbrock, Offenhauser, Isky, Moon, as well as others that would be used during the production run of the GT350 Mustang; Berry Plasti-Glass (fiberglass), Buddy Bar Castings (aluminum), Ray Brown Automotive (seatbelts), Traction Master (suspension) and Cyclone (headers and glasspacks). This provided Cantwell with several sources, all fairly local, for manufacturing special and unique parts. If one company was not able to meet the production needs, another one could be found. Cantwell enlightened us on the drafting of the GT350 parts, "Design drawings of some of the critical fabricated GT350 parts, like the traction bar brackets were developed. Most parts were made from prototype samples and later drawn. By the middle of 1965, we probably had drawings for most of the parts that could be drawn and partial sketches with critical dimensions for others. In fact, I did not even have a formal parts list for the 1965 GT350's, the first one was completed for the 1966 GT350's and was published in January of 1966." Jerry Nuznoff, who was a Ford high-performance purchasing/sourcing specialist, was assigned to Shelby American to help source and procure purchased parts for the GT350 program as well as to reassign sources when changes or new parts were required. Nuznoff was the person responsible for writing the purchasing contacts for the major pieces and was involved in the GT350 project from the very beginning, having some of the suppliers already lined up when Cantwell returned in October 1964. Another vital person for gathering the GT350 parts needed was Gordon Goring. Goring was Shelby's purchasing person for the smaller parts. Most of the purchase orders were, in fact, from Shelby American, with Ford's guarantee if it was needed. By this time we feel there were already three stock white, HiPo 289 Mustang fastbacks at Shelby American. These three Mustang fastbacks had "SFM5001", "SFM5002" and "SFM5003" written on their firewalls with a red felt pen. These three cars did not receive their Shelby American serial numbers and VIN tags until late May, early June 1965. When these three cars were being developed at the Venice plant, "SFM5001" was determined to become the first street car, "SFM5002" and "SFM5003" were the factory racecars. It was when the VIN tags were applied six months later that they were not put on the appropriate chassis. Cantwell added that these three cars were driven off the San Jose Ford production line, since it was the only way they could have been produced at that time. An area we are not sure of is if two of the first three cars that were destined to become R-models were already stripped of hoods, interiors and sealer at the San Jose plant? Was there enough advanced thinking to know this prior to those two cars going down the line or were the cars sent to Shelby American and then at that point, they stripped of their worthless street parts? A close inspection of 5S003 in March of 2004 yielded the discovery that the first street car delivered to Shelby American came with a rear seat intact! How many other stock Mustang parts, such as the hood, were still on 5S003 when it arrived at Shelby's Venice plant may never be known, unless the employee(s) who removed these parts is located. Any parts that had to be removed from these Mustangs at Shelby American were usually scrapped since they were considered to be "used ” and could not be returned to the San Jose Ford plant. Cantwell has remembered that the San Jose plant could have built one car as a special order if needed, but for convenience, they would have preferred to produced these cars in batches as was to be seen in future Shelby American orders. Cantwell feels by this time they knew, for the most part, what they wanted deleted, what the Ford production line could delete, but the exact specifications had not yet been determined. Some areas, such as producing a car without seam sealer could have been accomplished with a simple phone call to the San Jose Ford plant. In recently viewing 5S003, it was noted there was no seam sealer in the trunk, but there was along the underside of the floor pans. The sealer may have been removed in the trunk area when the car was re-restored in 1980. 5R002, a generally unrestored car at the Shelby American Museum in Boulder, Colorado has yielded that it arrived at Shelby American without it's rear seat. Perhaps the first two racing versions of the GT350 production were already deleted of some of the street parts which were already determined not to be used on the racing versions. 5R001 was restored in 1977 has not been viewed publicly for a number of years now, so we will focus our ideas on how the first two R models arrived based on the findings we will gather from 5R002. What we do know is that two of the cars became factory racecars, one was the B production 1965 champion and later was tagged SFM5R001, the other was the first race car produced which became the developmental race car "mule", initially referred to as 5002 and was later tagged SFM5R002. The first car completed which originally had SFM5001 written on its firewall, became the prototype 1965 GT350 streetcar and was later tagged SFM5S003. The initial groundwork of the GT350 program had already been set up, with Miles working on the suspension modifications while Brock was involved in the car's exterior, graphics, and badging. Cantwell had numerous deadlines that had to be met by Christmas, 1964. They were: To determine the list of unique parts needed for both the street and R model versions as well as having a source available for each part. As with any new project, there were some developmental problems that occurred throughout the 1965 model year. A second point on the checklist was to have a prototype street version in place for publicity use. There also had to be one racing version available, which was 5R002. The second R-model, 5R001, was not finished until considerably later in 1965. A fourth area to have completed by Christmas, 1964 was to produce eleven pre-production cars for public relation purposes. These cars are stated in the SAAC registry as not being finished until the middle of January 1965. Most of these initial cars were used by automobile magazines for road tests, some were used as factory demonstrators and a couple were sent back East, at least one was sent back to Ford. Finally, there had to be a total of 100 cars (both street and race versions combined) for the SCCA homologation meeting on January 1, 1965. I always thought these 100 or so cars had to be fully operational GT350's, but again from the SAAC registry, a lot of these cars did not run through the GT350 production line until February 1965, the last ones of that batch were not being finished until late April 1965. So obviously, when SCCA came out to Shelby American, the 100 (actually 113 cars by SAAC's factory records) cars that were lying around were the special build or "knockdown" Mustang versions as they were delivered from the San Jose plant. The December 12, 1964 issue of Competition Press confirmed this by describing for the first time in SCCA history that they were requiring certificates of production from manufactures before finalizing their decision to classify a new car for racing. At that point in time they had not heard from Shelby that the 100 cars were ready. The article also mentioned that the SCCA was going to send a member from their classification team to Shelby American by December 15, 1964 to verify the GT350's production. The SCCA was going to be "hard nosed" about the newly imposed December 31st/ 100 car regulation, but it would ultimately be up to the competition board of the SCCA. The 427 Cobras were not homologated by the FIA for the 1965 racing season, the cars had not arrived in sufficient numbers from England, but it did debut with Bob Bondurant driving CSX3002 along with Miles driving 5R002 at Green Valley, Texas in February, 1965. At this point, the momentum which the 289 Cobras had from the 1964 racing season carried over to 1965, eventually winning the FIA World Manufactures Championship for GT cars. Since it was already determined that Shelby was not going to have enough time to produce the 100 cars needed, the question was posed to the SCCA; what constituted the level at which the cars had to be completed? SCCA's response was that Shelby American had the component parts on hand and if they were producing, say five cars per day, that it would fulfill the spirit of the new requirement. As to the time limit given to get all 100 cars finished, they would be allowed 60 days past the initial deadline, that would have made it March 1, 1965, which was still before the SCCA national races began. The other area which is a little gray is the fact that the vacant lot between the two Shelby American Venice plants was able to fit maybe 50 of the Mustang fastbacks there, but where could they put all the rest? By December 1964, the writing was on the wall, the Venice plant was just too small for the additional production line needed for the GT350 project. Again, going back to the December 12, 1964 issue of Competition Press another article stated that Shelby American still had not moved to the LAX facility and they may not do it at all! Cantwell added the reason for this was that it took some time to convince the airport authorities that Shelby American was going to do something aircraft related in order to take over the existing lease.

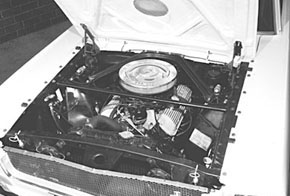

To our best knowledge, we feel 5S003 arrived at Shelby American with a Ford toploader transmission since that is how ALL HiPo 289 Mustangs left the San Jose Ford plant. At some point, the same aluminum transmission with special nickel "Sebring" gears as the 289 Cobra (5 bolt motor) found their way into this GT350 (6 bolt motor). Bill Moir, 5S003's first public owner, (after 6/15/65) distinctly remembers it having a T-10 transmission with an aluminum front case but a steel tailshaft. Another point to remember is that these three initial cars arrived at Shelby American without the export brace. Cantwell toured the San Jose plant with Sam Smith and Jack Khoury (the GT350 production manager) in order to establish a final build configuration for the street and race GT350's. Cantwell, Smith, and Khoury already knew they were going to strengthen the front engine compartment with a cross brace between the spring towers. This idea was taken from Alan Mann's experience in the European road rallies. The second addition which proved to be the most beneficial in reducing flex while increasing the rigidity of the engine compartment came in the form of the export brace. This is where Cantwell first noticed the export brace being placed on cars being shipped outside of the United States. It was determined the export brace was essentially a no-cost quality and performance item which could easily be incorporated into the build schedule of the future Mustangs destined for Shelby American. The production people at the San Jose plant were very cooperative and from that point on the export braces were placed on all the Mustang chassis that were to be delivered to Shelby American. Smith also determined it to be more cost effective to have Borg-Warner ship the aluminum transmissions directly to the San Jose Ford plant and have them installed in the cars as they progressed down the production line rather than to have the transmissions installed later at Shelby American. This prevented the virtually brand new Ford top loaders from having to be disposed of as scrap or wholesaled, since none of these parts could be returned to the factory for re-installation on new cars.

Like Cantwell, Brock was also at one time involved at General Motors but he was in their styling department. Brock was the youngest person (19 years old) when he was there. The year was 1957 and eventually Brock worked on what was later to be known as the Corvette StingRay. Brock ended up moving to California and purchased a house adjacent to Riverside Raceway while he was still in the Air Force, stationed at a nearby Air Base. He became one of Shelby's first employees and one of the head instructors at the Shelby School of High Performance Driving at Riverside Raceway. Perhaps Brock is most widely known for the aerodynamic body design of the Daytona Coupe Cobra, a project that did not gain the initial acceptance of his fellow employees until it was tested at Riverside on February 1, 1964. It didn't help that Benny Howard, the designer of the famous Howard racing planes of the 1930's and by this time was a well respected figure in aerodynamics (of airplanes) also told Shelby the Daytona Coupe design would take over 500hp to reach 180mph. The Daytona Coupe ended up exceeding everyone's expectations on top speed, handling, stability, as well as something initially overlooked, fuel economy for the long European racetracks and endurance racing found on the 1964 FIA schedule. The Daytona Coupe ended up being the weapon Shelby needed, narrowly missing the World Championship in 1964, but winning it decisively in 1965. Shelby American potentially could have won the World Championship from Ferrari in 1964, as Brock noted, "Enzo Ferrari had felt that the Cobra would win at Monza, the last race of the 1964 season, so he used his influences and connections (also being Italian) to have the Monza race cancelled." The final tally for the 1964 season was: Ferrari 84.6, Cobra 78.3. Although this web site is devoted to the 1965 GT350 Mustang, it is difficult not to bring into the picture other projects and the people involved in those areas since it is was all contained within Shelby American. Deke Houlgate was Shelby American's public relations director in the early years, later taken over by Max Muhleman and his assistant Gordon Thorne. However, it was Brock who designed some of the early factory posters, the COBRA, COBRA, COBRA tee shirts as well as a lot of the early factory literature for the 289 Cobra. The Cobra hood and trunk emblems were designed by Brock. Brock was also the person who took great pride in how the factory team Cobras looked, determining the layout of the decals placed on their bodies, thus creating consistently beautiful racecars. In many ways, Brock provided a lot of "public relations" for Shelby American in virtually everything he touched. When Cantwell came on board, the styling development of the GT350 project was the responsibility of Brock and Skeet Kerr. The image they were trying to achieve with the new GT350 was to still have the general appearance of the recently introduced fastback Mustang, but that it was to look a little cleaner and more purposeful. When it was determined that all the 1965 GT350's were to be painted white in color, Brock had an idea. One of his first cars was a 1946 Ford convertible , which he painted white with two wide blue stripes. It was painted this way as a tribute to the Briggs Cunningham road racecars of the 1950's, which also raced in Europe. At the time, white with blue stripes was considered to be the American road racing colors in international racing. This was a way for the cars to be identified as to country of origin, red = Italian, green = British, silver = Germany. This is where the white base body color with twin blue Le Mans stripes that are forever linked to the 1965 GT350 came from. When the initial groundwork was finished for the front and rear suspension as well as the design work for the exterior of the car, three HiPo 289 fastbacks were ordered to Shelby American. One of the three cars became the street prototype car, 5S003. All the regular Mustang emblems were removed except for one of the small running horse front fender emblems which made it up to the drivers side of the grille since no one could agree on a unique GT350 logo! The only other Mustang insignia on the outside was the factory gas cap. When Ford and Shelby wanted a way to identify the car from the side, and after the name GT350 was established, it was Brock that came up with the Microgramma Bold GT350 characters for the side stripes. This was the similar style of letters used in the Cobra literature, but there was also a desire to reflect the rocker panel stripes, which were first used on the Ford GT40's.

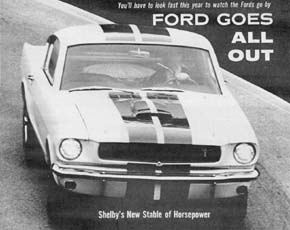

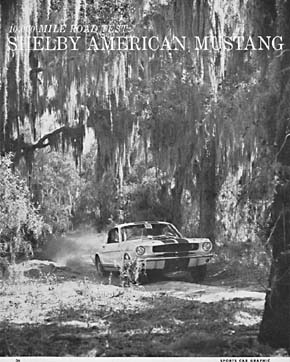

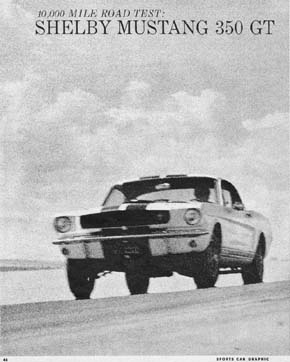

At this point, there was still not a toggle switch mounted for the horn, which in later development was located to the right of the stock Mustang instrument cluster. Brock's design work was evident in 5S003's interior once again when he produced a Cobra center cap for the 16" 289 Cobra wood steering wheel. This was accomplished by using a 289 Cobra hood ornament and a circular piece of black plastic to aid as the carrier. Once 5S003 was shipped to Cragar wheels on March 9, 1965 to receive its special sand cast, large hub, prototype Cragar wheels, it was Brock who designed the "CS" center caps. Later in production, he was the person responsible for the small GT350 emblem near the rear passenger taillight. When it came to public relations/advertising, it was Brock that handled the initial photo shoots of 5S003, but also provided the wording for the first set of GT350 ads. Brock handmade two small painted GT350 emblems that were unique to 5S003 and were placed on the side of the front fenders, directly behind the headlights. Likely these were to cover the two holes left when the 289 emblems were removed. Subsequent production cars were produced with emblems deleted so like the 6-cylinder Mustangs, the holes were never drilled for emblems. Brock and Kerr designed the fiberglass GT350 hood scoop, perhaps one the best looking of any car of its era. Shelby proudly displayed his new creation to the automotive press at Riverside Raceway on January 27, 1965. Frank Lance, a Shelby American mechanic remembers the day well. "There was a Ford press and management show at the Riverside race track. They had all kinds of Ford powered cars there to introduce to the attendees. Parnelli had his Lotus Indy car. Connie Kalitta had his 200mph dragster. Shelby had Cobras of all kinds as well as a GT40. There was an evening of dinning and drinking at the Mission Inn in town. All of these cars did a drive by near the grandstands on the backstraight for the people to see. The main attraction was the introduction of the Mustang GT350. There were ten of the cars (the preproduction prototypes -ed) for the press and management to drive around the track. For some reason, we Shelby mechanics had to ride with these drivers. I was not too keen to do this but did anyways. They flogged the cars around for most of the afternoon until some of the engines started to run rough. The mechanics found that the camshafts were wearing their lobes off. When the cams were made, the heat treatment was not done right, too soft. It was a little embarrassing for Ford but I guess they got it right and the cars became a success." For an additional $1,100.00 over what a regular 1965 HiPo 289 GT fastback cost, you got a complete package in the GT350 Mustang. Miles, Shelby, Cantwell, Brock and the other employees from Shelby American (whose names we will hope to know more of in the future) put together one of the finest road cars you could have bought in 1965 for $4,500.00, without having to add a thing to it. As William Jeanes once wrote when comparing a regular Mustang to the GT350, "One was a mannerly pony car that excelled in popularity, sales, and acceptance, a sensible "fun" car. The other was loud, rough, and scary........a pit bull of a car that stole your heart." Two weeks after its introduction, Miles staged his own St. Valentine's Day Massacre at Green Valley, Texas when he came in first place in the first race the GT350 was entered in. The race produced my favorite photos of an R model, 002, with all four of its wheels off the ground. Bob Jackson took the photos on a cold February 14, 1965 morning. Jackson, who won the Pulitzer Prize for photography in 1963 for taking the famous picture of Jack Ruby shooting Lee Harvey Oswald, took photos from a couple of different angles, on one shot, if blown up you can see Miles smiling. In another photo you can see the expression of a spectator in the background. Priceless. The competition version of the GT350 dominated B production SCCA racing, beating the Corvettes and Jaguar E-types in 1965, 1966 and 1967. By May of 1965, the moving of Shelby American from its previous location at 1042 Princeton Drive in Venice to its new home at 6501 West Imperial Highway in Los Angeles was preceding along smoothly. 5S003 was moved over to its new home in preparation for a few other changes and then an intense series of photo shoots that would yield the pictures to be used for the factory GT350 ads as well as some of the photos seen in the various road tests. Once again, there was not a lot of time in order to have 5S003 ready and the deadlines of the automotive magazines met for the introduction of this new model.

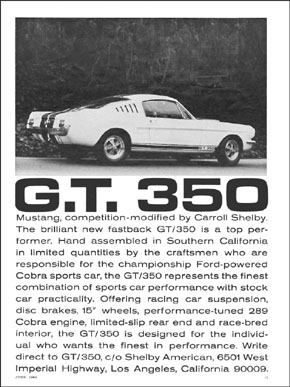

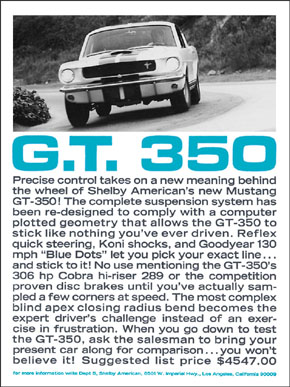

Drawing back to the birth of the 260 Cobra, when there was only one car finished, Shelby had it repainted a different color for the next insuing magazine to test the car, this gave the perception that there was more than one Cobra. In a way to expedite photographic variations for promoting the new GT350, a pair of Kelsey Hayes steel wheels were left on the drivers side, while two of the prototype Cragars were on the passenger side. This provided a simple, but effective way to show that there was a couple of wheel variations that could be ordered for a GT350. Brock took 5S003 as well as either Eric Hoopingarner or Kerr to Coldwater Canyon in Beverly Hills, California for what was to produce the photos used in the initial GT350 factory ads, as well as gracing the pages of several automotive magazines carrying road tests on the new GT350. There were three initial ads produced for the 1965 GT350, 5S003 was use for two of them. One of the ads carried a photo located at the top of the page showing the passenger side of 5S003. Below this photo was the bold G.T.350 in the microgramma characters. The ad layout was also designed by Brock and started out by stating "Mustang, competition-modified by Carroll Shelby." A second ad featuring a photo of 5S003 was a head on shot, which became a widely publicized photo with a different caption. This time the Brock creation started out by stating, " Precise control takes on a new meaning behind the wheel of Shelby American's new Mustang GT-350!" There were multiple photos taken at several different angles and elevations taken during this shoot. Most angles show the steel wheels on the drivers side, but as the camera was moved to the passenger side a shinny chromed Cragar rim can be seen. Another group of publicity photos were taken of 5S003, this time the location was at the Shelby American factory at LAX and the driver was the other instructor from the Shelby School of High Performance Driving, John Timanus. Timanus was brought aboard to help co-instruct the school along with Brock until Brock was asked to devote his time in designing the Daytona Coupe Cobra. At this point, Timanus was given the sole responsibility of the driving school which he incorporated methods which are still used today at various other driving schools, he passed away on August 6, 1988. In these photos of 5S003, Timanus was wearing his easily recognizable helmet while driving around a cone which gave the perception of an autocross or racecourse. Most of the photos this time were taken of the drivers side, but again at different elevations. The Brock designed GT350 emblems behind the headlights are best viewed in these photos. In another photo taken lower to the ground provides a view that 5S003 did have a Cobra t-oil pan at that time. An April 19, 1977 Old Cars Newspaper shows the only photo I have seen of 5S003 going around a different set of cones this time from the passenger side with the early Cragars still present. A few publications have printed a side shot of 5S003 taken at the same time with a fence and LAX in the background. One interesting area in regards to this photoshoot was the absence of the gauge pod from the middle of the dash. Perhaps Brock's mock-up pod and gauges just sat in the dash for the actual photos and an actual functioning pod and gauges were installed at a later date?

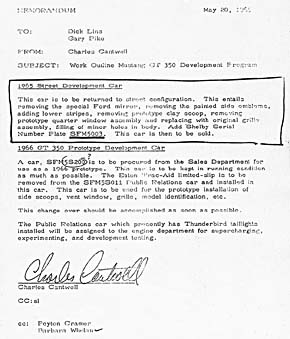

Obviously, Christy fell head over heels for the new GT350. Upon returning to Shelby American from his extensive road trip, he immediately purchased one, which turned out to be 5 015, the first regular production GT350 built. As of August, 1969 he had racked up 84,000 "hard" miles on the car, unfortunately, Christy, who could have given us some more insights to these early cars passed away in 199?. Shelby American benefited from the positive feedback it received from the various national automotive magazines after they had road tested the new GT350. In May 1965, Car and Driver, Road and Track, Motor Trend, Motorcade, Car Craft and Road Test all published road tests on the GT350. For June 1965, Mechanix Illustrated, Car Life and Custom Illustrated had magazines about the new car from Shelby American. By June of 1965, the prototype street GT350, 5S003, had served its purpose. There were now plenty of GT350's rolling down the production line, all the necessary publicity photos had been taken and the development of 5S200 and 6S001 had begun in order to determine the styling changes for the new 1966 GT350. It is not uncommon for prototype cars to be destroyed, at least at large automotive factories, after it is determined they have completed their original intent. If this was done to 5S003, it may have eliminated the possibility of Shelby American-Ford being sued over an accident resulting from the sale of a car, which did not meet the exact specifications of the actual production cars. In this particular case, 5S003, could easily be put into production configuration and therefore command the value of a "used" GT350, so for this reason, the prototype 1965 GT350 street car was not destroyed. On May 20, 1965, a memo at Shelby American was passed from Chuck Cantwell to Dick Lins and Gary Pike, two Shelby American employees. The memo spared the life of 5S003, as well as providing some other insights as to how this GT350 was used as a test bed for other exterior features. Having a photograph of 5S003 within a few days after this memo was circulated allows us to observe this historical car being converted from its prototype stage into a regular street GT350 at LAX. This photograph was widely used as part of the 1965 Shelby American Press Kit, which was developed by Gordon Thorne, the Shelby American public relations assistant under Muhleman.

The memo stated, "This car is to be returned to street configuration. This entails removing the special Ford mirror, removing the painted side emblems, adding lower stripes, removing prototype clay scoop, removing prototype quarter window assembly and replacing with original grille assembly, filling of minor holes in body. Add Shelby Serial Number Plate SFM5003. This car is then to be sold ." Taking one item at a time , it is safe to say, that when 5S003 left Shelby American it looked just like any other street GT350 at that time. If a part was needed to take 5S003 out of the prototype stage, it was probably just grabbed off the parts bins from the cars going down the assembly line. The GT350's in production at that time would have been around the serial number of 5S280. The prototype Cragar wheels were removed and the car left Shelby American with four Kelsey Hayes steel wheels, which is the way Moir remembers purchasing the car. The mocked up center cap for the steering wheel was removed and a proper Cobra center cap was added. We are not sure what "special Ford mirror" was once placed on 5S003 while at Shelby American, but it appears to be a Talbot jr. mirror mounted near the rear of the front fender. The removal of the painted side emblems refers to the Brock designed "GT350" located behind the headlights, once unique to 5S003, is no longer seen in the race shop photo. The addition of the lower GT350 side stripe is due to the fact when 5S003 was initially created, there were no 3M GT350 stickers available, so it was done by hand, resulting in non uniform character size and spacing of the " G . T . 3 5 0 " within the side stripe. As seen in the photo, the GT350 side stripe has been completely removed, the new stripe has yet to be applied. Cantwell feels "Removing prototype clay scoop" was referring to a mocked up clay side brake scoop, similar to the one that was done on the Jerry Titus R model and perhaps another car for the prototype 1966 model. We have no photos of 5S003 having a side brake scoop, but perhaps this was done to the drivers side so it is not apparent in this photo. The photos taken of the brake scoop could have been so detailed in nature it would be impossible to tell if in fact it was mounted on 5S003 or another GT350. Cantwell feels there was more than one scoop design and that multiple cars may have had them installed temporarily. Moir added side brake scoops himself and did not see any evidence of this ever being done prior to him, but Cantwell quickly pointed out that clay sticks to metal and therefore there may not have been any "evidence” of the scoop ever being there. The next line of the memo states "removing prototype quarter window...." which actually pertained to 5S200 since it received the initial "1966" type quarter window treatment and not 5S003. Cantwell feels that some form of a modification had to be present, it may have been a "check fit" to determine if there was a production variation from one Mustang to another which may have affected the quarter windows being installed. If this were so, it would not have required the internals of the side vents to be cut. It would also explain why Moir saw no evidence of the metal pillars behind the side air vents ever being tampered with when he added quarter windows to 5S003. I talked to Mike Sangster, a fabricator at Shelby American who remembers distinctly being told by Cantwell to fabricate the quarter windows and in doing so he removed the metal pillars by use of a ball peen hammer. Needless to say, the removal of the metal was not very "clean". Cantwell also felt that perhaps Sangster was not the person who did the initial quarter window modifications and that it was definitely not performed solely with a ball peen hammer. The filling of the minor holes in the body may, as Howard Pardee suggested, mean to be a second attempt at making the holes flush where the original Mustang emblems were mounted on the side of each fender. For the actual GT350 production cars, the front fender holes were simply deleted during production by the use of six cylinder Mustang fenders being specified. This may be why Brock developed the unique GT350 emblem seen in some of the photos of 5S003- in order to cover the holes left when the 289 emblems were removed. Cantwell felt these holes were in reference to mounting the Talbot jr. mirror, which was once present on 5S003. While 5S003 was recently on a hoist, we looked from underneath at the inside of the properly date coded passenger side front fender and did locate at least three holes that were filled (two were in a vertical orientation) near the lower section of the fender. These holes corresponded to where the stock Ford Mustangs had a horse emblem as well as a "mustang" nameplate mounted.

As Schwarz, recently told us, " It was when we were getting ready to move to the airport facility from the Venice plant. At this time, none of the cars had ID tags on them. They were afraid that with the vast amount of cars, parts and equipment being moved, that a car without an ID tag could "disappear." My boss, Chuck Cantwell, called me to his office and gave me three ID tags and said "put these on those cars", he didn't say which car got what, so I just put one on each car. The mistake was not discovered til many years later. I did not even know what the designations of "S" or "R" meant!" So it really was a random shot which of the first three cars received their Shelby American VIN tag on that day! The next document we have on 5S003 is the Shelby American invoice dated June 15, 1965 in which the car was transferred to Shelby American's dealership/showroom; Hi-Performance Motors at a cost of $3,281.40. We are not too sure how long 5S003 was at Hi-Performance Motors before it was returned to Shelby American and picked up by Red Geesaman. Geesaman was one of the salesmen at Ed Leslie's (a Cobra team driver) Motors in Monterey, California. I recently spoke to Geesaman who remembers the car well, he referred to the car as one of several "press cars" which had about 1,000 miles logged on its clock. 5S003 was driven up to Monterey, California where it was used as a demo car at Leslie's Motors. I spoke to Ed Leslie, but he does not remember 5S003 or any of the other GT350's his dealership sold at that time, he passed away on March 31, 2005. Moir visited Leslie Motors in July? 1965 and purchased 5S003 through Geeseman for $4,350.00 which seemed to be a lot of money for a moderately used, Kelsey Hayes steel wheeled, GT350, considering most of factory literature listed a new car at $4,547.00. Moir mentioned there were a handful of 1965 GT350's present at the dealership that day, 5S003 being the only used one. We do have a hand written sheet from Shelby American dated August 2, 1965 listing twenty-six 1965 GT350's and it still had 5S003 as "available for sale". Moir has always been a "car guy" which makes it a treat to talk with him. He has a very clear memory of how 5S003 was set up when he purchased it in 1965. A short time after purchasing 5S003, Moir heard something rattling near the back of the car. The noise was tracked down to beneath the rear shelf, when the rear shelf was removed an unused 289 Weber intake manifold was found! My only thought is that a Shelby American employee placed the intake in the back of 5S003 and when a co-worker was putting in the rear shelf perhaps his line of sight was blocked by the size of the shelf and the intake was covered over. Moir can still remember 5S003's original license plate number (EVC839) and will never forget when the wood steering wheel came off in his hands while he was driving the car since there was no locking nut on the hub. As mentioned before, he was positive the T-10 transmission front case was made of aluminum while the rear tailshaft was steel. All the early photos Moir had taken of the car, except one, were destroyed in a house fire. Moir modified the car with some of the 1966 GT350 features as well as installing a roll bar and fabricating an R model gas tank. The car was sold to the Don Wester Porsche dealership in Monterey, California. I have talked to Don Wester but he could not provide any information about the car or whom it was sold to. 5S003 was repurchased in 1967 by Moir with the assistance of the California DMV tracking down its license plate number . The fenders had been flared and the car was repainted several times so Moir stripped the car back down to bare metal and repainted it to the original colors. Today, Moir is still heavily involved in cars, mainly restoring Can Am McLarens. We are going to continue to do research on 5S003 until all leads, no matter how small, are explored. This car deserves it, 5S003 is the history of the street GT350. We are interested in how 5S003 appeared in its prototype stage from November 1964 through May, 1965. We welcome others help in contributing information or leads on 5S003. If you have anything to add to this web site, no matter how trivial it may seem, please contact us! Mark Hovander As of January 9, 2006 Special thanks for help in this article by: (Place your mouse cursor over a name to see a picture)

|

|||||